GlobeCore’s Invitation to IEEE PES T&D 2020

GlobeCore’s Invitation to IEEE PES T&D 2020 GlobeCore would like to invite all our partners to attend IEEE PES Transmission and Distribution Conference and Exposition (T&D 2020), to be held on 20-23 April in Chicago. IEEE PES T&D is one of the most prominent forums in the energy industry. This year, IEEE PES T&D expects over 14000 visitors to discuss industry trendsRead More

GlobeCore extends invitation to the International Construction & Utility Equipment Exposition-2019

GlobeCore extends invitation to the International Construction & Utility Equipment Exposition-2019 GlobeCore invites all businesses and parties interested in the implementation of innovative technologies to the International Construction & Utility Equipment Exposition. This event is biannual, and this year will be hosted by Kentucky Exposition Center, Louisville, Kentucky on 1-3 October. The exhibition focuses, among other things, on electric power transmission and distribution, wastewater treatment, naturalRead More

GlobeCore Invitation to Transformador LatAm 360

GlobeCore Invitation to Transformador LatAm 360 Transformador LatAm 360 symposium, dedicated to transformer lifecycle, will be held in Panama on 10-13 September this year. The four day event will include presentations from the leading companies in the industry of transformer servicing and lifetime extension: SDMyers, Megger, Maschinenfabrik Reinhausen, Omicron, GlobeCore, Qualitrol and Transformer Clinic. The presented information will help improve transformerRead More

GlobeCore to Hold a Seminar in Angola

GlobeCore to Hold a Seminar in Angola GlobeCore continues with the policy of holding seminars on electrical insulation oil treatment and transformer lifetime extension around the world. The next seminar is planned for the 27 June in Luanda (Angola). We invite all representatives from the electric power industry in Africa and elsewhere to visit the event. The seminar will provide up toRead More

GlobeCore at China International Electric Power Exhibition-2019

GlobeCore at China International Electric Power Exhibition-2019 GlobeCore representatives took part in the 19th China International Electric Power & Electric Engineering and Smart Grid Exhibition in Shanghai on 21-22 April. Here is a brief photo report from the conference.

GlobeCore Extends Invitation to Visit AWEA WindPower-2019 in Houston

GlobeCore Extends Invitation to Visit AWEA WindPower-2019 in Houston GlobeCore would like to invite everyone involved in the alternative energy market to visit one of the main events in industry: AWEA WindPower-2019, which will be held 20-23 May 2019 in Houston, USA. The conference will focus on important issues and topics of interest in the wind power generation industry. At the event, GlobeCore can beRead More

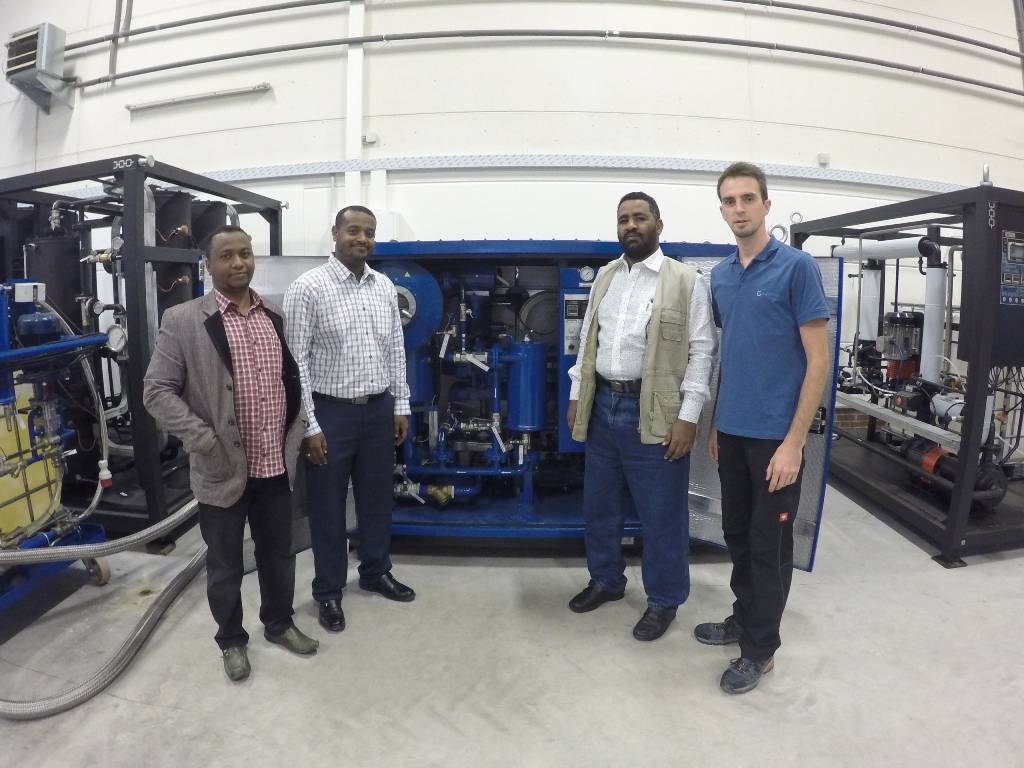

Commissioning of GlobeCore Equipment in Bangladesh

Commissioning of GlobeCore Equipment in Bangladesh GlobeCore equipment was commissioned in Dhaka, Bangladesh, in the first quarter of this year. One of the local electric power companies purchased a CMM-4 and a CMM-6 units to service their power transformers. This type of equipment is well suited for such tasks as: 1) removal of particulate matter, water and gas from transformer oil;Read More

The New CMM-1CF for Purification of Oil with Very High Water Content

The New CMM-1CF for Purification of Oil with Very High Water Content GlobeCore has successfully completed the final trials of the CMM-1CF unit with the processing rate of 1 m3/hour in May. The primary mission of this product is not only filtration, but also removal of water from industrial oil. The unit can process oil with water content of 50% and more. The CMM-1CF can process dieselRead More

Ongoing Cooperation With Electric Power Industry of Malaysia

Ongoing Cooperation With Electric Power Industry of Malaysia Only recently (in January), GlobeCore presented and commissioned equipment in Malaysia. Several weeks later, new products were commissioned. Seven CMM-4/7 units began operation in several Malaysian cities on 19 March – 8 April. This product enjoys high demand due to its versatility. The СММ-4/7 are instrumental in several operations important for transformer installation, repairs andRead More

Modern Electric Energy Industry Solutions Presented in Oldenburg

Modern Electric Energy Industry Solutions Presented in Oldenburg On 12-13 March 2018, GlobeCore hold a presentation of the modern solutions for the electric energy industry (oil processing, transformer and wind turbine servicing) in Oldenburg in cooperation with Maschinenfabrick Reinhausen and Seifert Transformatorentechnik. The presentation was attended by representatives of 14 companies from 6 countries (Germany, USA, Great Britain, Italy, UAE and Nigeria). GlobeCore presentedRead More

GlobeCore has organized and conducted a seminar in the USA

GlobeCore has organized and conducted a seminar in the USA March 2-3, 2018 in Houston, GlobeCore held a seminar for representatives of the Texas electric power industry. During the seminar were discussed the issues of aging processes in electrical insulating oils influencing the efficiency of power transformers, including a report on the topic “Purification and regeneration of transformer oils with GlobeCore equipment”. The practical partRead More

Presentation of GlobeCore equipment in Oldenburg

Presentation of GlobeCore equipment in Oldenburg March 5, 2018 a regular presentation of oil purification and regeneration equipment was held in the International Training Center of GlobeCore (Oldenburg, Germany). This time the event was attended by representatives from Bosnia and Herzegovina, and their partners from Qatar. First of all, the guests were interested in the possibilities of GlobeCore equipment for processingRead More

GlobeCore in the press : “Wind Systems” magazine

GlobeCore in the press : “Wind Systems” magazine The second issue from February 2018 of the leading magazine in wind energy “Wind Systems” Magazine, published a Frank May article, entitled “Changing Turbine Gearbox Oil”. The articles discusses the main points to pay attention to when servicing the gearboxes of wind turbines and, in particular, the oil change. It shows the advantages of theRead More

The oil treatment station CMM 4/7 commissioned in Kuala Lumpur

The oil treatment station CMM 4/7 commissioned in Kuala Lumpur January this year, the engineering team of GlobeCore came to Malaysia (Kuala Lumpur), to present and commission equipment. This time, the CMM-4/7 unit was put into operation, designed for degassing, drying, cleaning from impurities and heating transformer oils used in power transformers. This equipment is multifunctional, as it can also perform heating of oil-filled equipmentRead More

Commissioning in the USA

Commissioning in the USA In the end of December 2017, GlobeCore specialists visited the United States, commissioning a CMM-10TS unit in a suburb of Chicago. This unit is different from our stock products, since it was built to employ heat and vacuum to remove water from highly viscous industrial oil. During the commissioning, the unit was able to removeRead More

Participation in IEEE PES T&D Conference & Exposition

Participation in IEEE PES T&D Conference & Exposition The 2018 IEEE PES Transmission & Distribution Conference & Exposition isn’t just the industry’s signature show — it’s an all-encompassing, immersive and global conference experience like no other. Here you’ll join top utility CEOs and some of the world’s brightest engineers in discovering the latest T&D products, ideas and innovations leading the industry forward toRead More

Participation in AWEA Wind power conference and exhibition

Participation in AWEA Wind power conference and exhibition Professionals from all over the world attend to network, learn, advance their organizational mission and to participate in the largest wind energy exhibition in the Western Hemisphere. More major product announcements and exciting releases happen here, than at any other wind energy industry event. http://www.windpowerexpo.org GlobeCore and GC Technologies will also have a booth inRead More

GlobeCore invites to the seminar in Texas

GlobeCore invites to the seminar in Texas In our constant effort to provide a superior product with exceptional service, we are pleased to announce the opening of our new sales office and service center, complete with technicians and inventory, in the USA. Our new dealer, Dave Wilson, with GC Technologies, at 1110 Paige St, Houston, Texas 77003, 713-699-3388, [email protected], 713-202-7983 (cell) isRead More

Colombia hosted an international exhibition Feria Internacional del Sector Eléctrico 2017

Colombia hosted an international exhibition Feria Internacional del Sector Eléctrico 2017 The exhibition Feria Internacional del Sector Eléctrico was established in 2006 and every two years brings together representatives of the electrical industry of Latin America and guests from other countries. This year GlobeCore took advantage of the opportunity and took part in this event, which was held in Medellin (Colombia). From November 29 to DecemberRead More

GlobeCore Presentation in the Philippines

GlobeCore Presentation in the Philippines Frank May of GlobeCore visited the Philippines on 4-7 December to demonstrate the capabilities of the company’s regeneration equipment. The presentations were held in five cities of the island nation: Bulacan, Marilao, Valenzuela, Cabuyao and Consolacion. Representatives of the oil refining industry received general information on the design and capabilities of GlobeCore products. Frank MayRead More

GlobeCore Regeneration Equipment Presentation in Qatar

GlobeCore Regeneration Equipment Presentation in Qatar GlobeCore representatives visited Doha, Qatar, to showcase the company’s equipment for regeneration of electrical insulation oil. The presentation’s objective was to familiarize representatives of the Qatar electrical power industry, including KAHRAMAA (Qatar General Electricity & Water Corporation), which supplies the country’s population with power and water, with the capabilities of GlobeCore equipment. Also were present theRead More

GlobeCore Opens a New Service Center in Costa-Rica

GlobeCore Opens a New Service Center in Costa-Rica Dear friends! We are happy to announce that a new service center commenced operations in Costa-Rica in November 2017. This service center will assist our clients throughout the Latin America. A stock of spare parts will be made available to the clients. It is also possible to visit the new service center to purify andRead More

A seminar on purification and regeneration of industrial oils will be held in Costa Rica on 4 May

A seminar on purification and regeneration of industrial oils will be held in Costa Rica on 4 May Dear customers and partners! GlobeCore invites you to attend a seminar on purification and regeneration of industrial oils, which will take place on May 10 in San José (Costa Rica). Seminar program: Discussion of the influence of oil aging processes on the efficiency and operation of power transformers; Report on ” GlobeCore oil regeneration units“; DemonstrationRead More

СММ-2,2 project was executed in Italy

СММ-2,2 project was executed in Italy September 17, GlobeCore started up and tested a CMM-2.2 unit in Foligno (Umbria), Italy. This time, the startup and commissioning were carried out on site of a large locomotive manufacturer in Italy. Italian railers use silicone oil in their locomotive transformers. The oil mostly consists of silicon atoms, its name comes from Latin “silicium” (silicon).Read More

Novelty in oil purification equipment at GlobeCоre

Novelty in oil purification equipment at GlobeCоre GlobeCore is a developing company that continues to please its customers by designing new equipment and improving old units. In September, the company presented an upgraded degassing equipment for transformer oil – CMM-1H. It is an improved version of a mobile oil station – CMM-1.0. Like the previous model, the new unit operates on theRead More

A seminar on purification and regeneration of industrial oils will be held in Oldenburg on 24 October

A seminar on purification and regeneration of industrial oils will be held in Oldenburg on 24 October Dear customers and partners! GlobeCore invites you to attend a seminar on purification and regeneration of industrial oils, which will take place on October 24 in Oldenburg (Germany). Seminar program: Discussion of the influence of oil aging processes on the efficiency and operation of power transformers; Report on ” GlobeCore oil regeneration unit CMM-R “; DemonstrationRead More

“Mojave Heat-100” is a compact hot air drying unit

“Mojave Heat-100” is a compact hot air drying unit Most stages of maintenance and repair work on power transformers require depressurization of their active part. Depressurization can result in wet atmospheric air getting into the windings insulation, which is undesirable. To prevent this happening GlobeCore produces a “Mojave Heat-100” unit, the last model was shipped to the Customer in September. The equipment carries outRead More

Commissioning of regenerative equipment in Spain

Commissioning of regenerative equipment in Spain August 16 this year in Seville, Spain was completed the project of putting into operation a CMM-2R plant for transformer oil regeneration. The plant includes all elements needed to perform regeneration of transformer oil properties (filters, regeneration columns, pumps, tanks, electrical control cabinet, etc.). This equipment can work in the following modes: automatic regeneration ofRead More

СMM-2,2 plant was started up in Jizan

СMM-2,2 plant was started up in Jizan August 8, 2017 our company’s operation personnel performed commissioning and adjustment of the CMM-2.2 unit in Jizan (Saudi Arabia). This equipment is multifunctional, since in addition to cleaning insulating oils from mechanical impurities, water and gases, it also heats electric equipment with hot oil and vacuum drys power transformers. The plant’s capacity in drying andRead More

Equipment presentations every year in Zimbabwe

Equipment presentations every year in Zimbabwe A year ago, GlobeCore held presentations in the capital of Zimbabwe, Harare. Unfortunately, not everyone was able to participate in the events. Therefore, our company was happily to give another opportunity and to hold a series of presentations, this time in Bulawayo in June 8, 2017. The main attention was given to the electrical industryRead More

CMM-4/7: now in Finland

CMM-4/7: now in Finland On May 31, 2017, the CMM-4/7 unit started its operation in Helsinki (Finland). First it serviced a 400 MVA transformer. CMM-4/7 is a multifunctional unit – it has three modes of operation: First the unit warms up and then it starts processing oil in degassing mode. In this mode, the oil is heated to aRead More

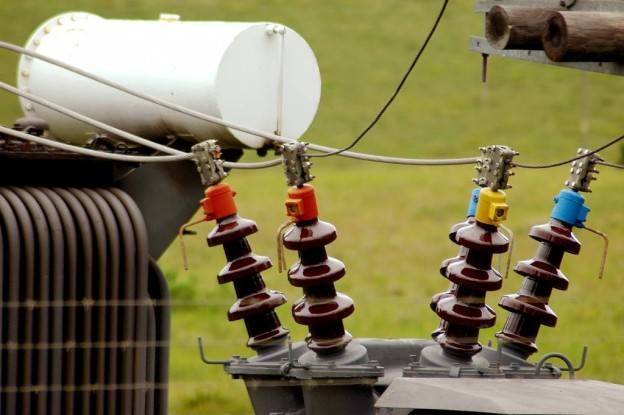

CMM-4/7 and CMM-12R installed and commissioned in Botswana

CMM-4/7 and CMM-12R installed and commissioned in Botswana In May, 2 more installations of GlobeCore equipment took place. At this time in Gaborone (Botswana) were put into operation two new units CMM-4/7 and СММ-12Р. CMM-4/7 processes insulating oil (through drying, degassing, cleaning from mechanical impurities) and heats oil before refilling, it also vacuum dries and evacuates transformers. The degassing mode is designed forRead More

The number of GlobeCore equipment is growing in Pakistan

The number of GlobeCore equipment is growing in Pakistan May 13, 2017, the number of GlobeCore equipment in Pakistan increased by one unit. A CMM-4/7 unit was commissioned by the company’s engineering team in Lahore. This equipment performs heating of power transformers, as well as drying, cleaning, degassing and nitriding of insulating oil. CMM-4/7 provides: volumetric gas content below 0.1%; moisture content by weightRead More

GlobeCore presented a seminar In Quito

GlobeCore presented a seminar In Quito During 2 days, May 3-4 in Quito (Ecuador), GlobeCore held a seminar presenting its equipment The event was attended by representatives of the electricity industry from many countries, including Peru, Bolivia, Argentina, Colombia, Costa Rica and El Salvador. The seminar covered the following questions: General information about GlobeCore; Modern technologies in cleaning and regeneration ofRead More

GlobeCore held a presentation in Ecuador on May 3-4

GlobeCore held a presentation in Ecuador on May 3-4 May 3-4, in Quito (Ecuador) GlobeCore together with Tcontrol S.A. organized and held a seminar on modern technologies for cleaning and regeneration of mineral oils, fuels and other petroleum products. The event was part of a series of presentations held by GlobeCore. in order to raise the awareness of managers and specialists in the energy,Read More

CMM-0,6 unit is ready for transformer maintenance in Saudi Arabia

CMM-0,6 unit is ready for transformer maintenance in Saudi Arabia April 23 – 27, GlobeCore technical team visited Jeddah (Saudi Arabia). The purpose of this trip was commissioning of a CMM-0,6 oil purification unit. This equipment cleans insulating oil from mechanical impurities, water and gases. The unit’s components are assembled in a closed container and mounted on a single-axle trailer. The container has flap doorsRead More

Commissioning of CMM-4/7 unit in Tallinn

Commissioning of CMM-4/7 unit in Tallinn April 10, the CMM-4/7 unit (on a trailer) was commissioned in Tallinn (Estonia). This type of unit degases, dehydrates and cleans insulating oils from mechanical impurities. In addition to the functions mentioned above, CMM-4/7 can also be used for heating and pumping oil to and from oil filled transformers and other electrical equipment Designed onRead More

CMM-4/7 started up in Estonia

CMM-4/7 started up in Estonia April 10, 2017 GlobeCore specialists started up a CMM-4/7 unit in Tallinn (Estonia). This equipment is used by business engaged in installation, repair and operation of power transformers for degassing and filtration of insulating oil. Also, the units can be used to heat oil-filled electrical appliances with hot oil, for vacuum dehydration and evacuation ofRead More

Oil Refining Process

Oil Refining Process Oil refining process. Crude oil just extracted from the well in its original form has a very limited application. Therefore it is processed before it arrives on the market in the form of gasoline, fuel oil, aviation fuel, etc. In the early stages of the oil industry the refining process was reduced to primitive distillation.Read More

Compressor Oil: Properties and Removal of Impurities

Compressor Oil: Properties and Removal of Impurities Compressor oil is used in the industry as a lubricant for the valves and cylinders of compressors; it is also used as a sealing medium for compression chamber and piston rods. The main feature of that distinguishes compressor oils from other industrial oils is their operation in high-temperature environments and mixing with coolants. Therefore, compressorRead More

Drying of silica gel

Drying of silica gel Silica gel. The industry uses various adsorbents to remove excess moisture. Today, there are many types of adsorbents of natural and synthetic origin. A special place among the adsorbers belongs to silica gel. Silica gel is a dried gel obtained from oversaturated solutions of hydrated silica. The main feature of silica gel is its largeRead More

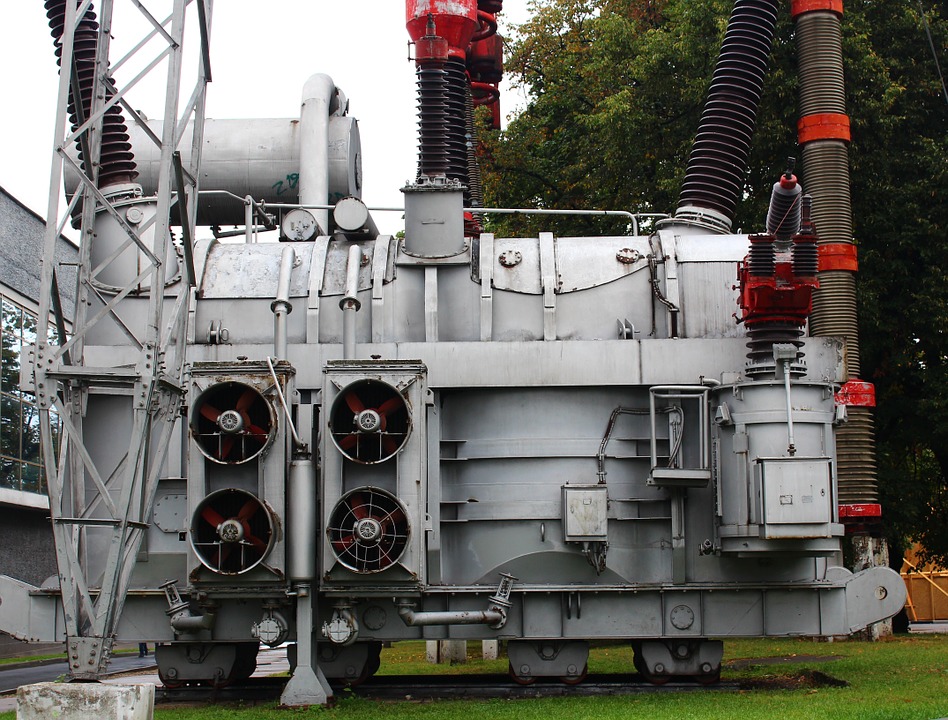

Diagnosis of Power Transformers by Insulating Oil

Diagnosis of Power Transformers by Insulating Oil Diagnosis of power transformers helps to identify potential problems and failures in order to prevent and remove them. It is recognized that the analysis of breakdowns of transformer insulation also detects anomalies in oil-filled equipment. For example, when metal parts of the transformer are overheated, the oil accumulates gases, carbon and metallic particles. The mostRead More

GlobeCore equipment started its operation in Indonesia

GlobeCore equipment started its operation in Indonesia In mid-February this year, GlobeCore representatives visited Indonesia (Gresik), where they commissioned the CMM-0.6M oil purification plant. This equipment cleans insulating oils from water and mechanical impurities. The oil is treated from cleanliness level of ISO – -/18/16 to cleanliness level of ISO – -/14/12 by multiple passes through the filter unit. A CMM-0,6M plantRead More

GlobeCore presented its equipment at Gulf Industry Fair 2017

GlobeCore presented its equipment at Gulf Industry Fair 2017 February 7-9, 2017, GlobeCore, together with RAY International Group, took part in Gulf Industry Fair 2017 (Manama, Bahrain) that covered different industrial sectors This event was first held in 2008. Since then it has become a leading industrial trade show in the Persian Gulf. Annually, this event is visited by the leading manufacturers of machineRead More

GlobeCore presented its equipment at Gulf Industry Fair in Bahrain

GlobeCore presented its equipment at Gulf Industry Fair in Bahrain February 7-9, 2017 Bahrain International Exhibition Centre hosted a Gulf Industry Fair 2017. The fair was held in Manama (the capital of Kingdom of Bahrain) and brought together the leading manufacturers of equipment for energy industry, environmental protection, metallurgy, etc. The exhibition was first held in 2008. Since then it was visited by more thanRead More

Oil Degassing The CMM-10-10 unit commissioned in Asyut (Egypt)

The CMM-10-10 unit commissioned in Asyut (Egypt) January 11 – 13, 2017, GlobeCore technical team visited Asyut (Egypt). They carried out the start-up and commissioning of the CMM-10-10 plant, which would service the power transformers at local substation. This equipment cleans insulating oils from mechanical impurities, water and gases, and also treats the power transformers with high vacuum. The unit operates inRead More

CMM-12R

CMM-12R The primary focus of GlobeCore is the development and production of transformer oil regeneration equipment. Among the methods of regeneration the most widely used is adsorption treatment. It is particularly effective for processing the oils containing dissolved products of aging. The adsorbent becomes gradually saturated and requires recovery of its properties. Generally, the reactivation processRead More

The USA: GlobeCore Equipment for Servicing Wind Farm Transformers

The USA: GlobeCore Equipment for Servicing Wind Farm Transformers GlobeCore’s standard range of services includes not only sales of equipment, but also rentals. It was the latter option that was chosen by one of American electric power companies to service the transformers of wind farms. Two CMM-4/7 units were contracted and went to the Virginia. This product is designed for: transformer oil degassing; transformerRead More

GlobeCore Cooperation With the US Power Industry

GlobeCore Cooperation With the US Power Industry GlobeCore strives to participate in all possible projects to replace traditional energy sources with alternatives. Some of the services GlobeCore offers our clients is the sales of equipment to process electrical insulation oil and servicing power transformers, as well as rentals of this equipment. It was the latter option that was chosen by one ofRead More

Fuller’s Earth Transformer Oil Regeneration System Canada. The CMM-4/7 unit successfully services transformers of wind turbines

Canada. The CMM-4/7 unit successfully services transformers of wind turbines GlobeCore is a member of the American Wind Energy Association (AWEA), and always tries to find solutions to the urgent problems in the industry. Among the tasks are: increasing reliability and extending service life of wind turbine transformers. These transformers convert the voltage of turbine generators for power lines. They are positioned within the towerRead More

Organize your own businesses with the purchase of waste oil

Organize your own businesses with the purchase of waste oil These days the Internet has adverts to “Buy waste oil.” These ads can cause some confusion and raise a number of questions. For example, why collect waste oil, which seemingly cannot be used as intended? Let’s try to understand. In most cases, these ads are from people or companies involved in regeneration of waste oil.Read More

Oldenburg. A Presentation for Ethiopian Guests

Oldenburg. A Presentation for Ethiopian Guests On 14 November 2016 GlobeCore held a presentation for visitors from Ethiopia. The presentation focused on equipment for purification of mineral oil and servicing of power transformers, along with a demonstration of oil purification equipment at GlobeCore International Training Center. The guests from Ethiopia were most interested by the regeneration technologies implemented in CMM-R andRead More

GlobeCore gains membership in the American Wind Energy Association (AWEA)

GlobeCore gains membership in the American Wind Energy Association (AWEA) Our company always strives to keep abreast of latest trends in the power generation sector. This approach allows us to follow the newest technologies to improve our equipment and solve practical problems. To be more involved with the wind power industry, GlobeCore joined the American Wind Energy Association (AWEA). This decision stems from the workRead More

GlobeCore at the 18th WETEX 2016 international exhibition

GlobeCore at the 18th WETEX 2016 international exhibition October 4-6, the International Exhibition Centre in Dubai (UAE) hosted the 18th WETEX 2016 exhibition. WETEX is an annual exhibition that first started in 1999 and which brings together the leading global experts in the fields of water, energy, technology and environment, as well as major investors. This year more than 1500 participants (700 companies)Read More

CMM-0.6 Startup in Italy

CMM-0.6 Startup in Italy October 5, 2016 GlobeCore engineers commissioned a CMM-0,6 unit in Carpenedolo (Brescia, Italy) Transformer oil purification plant CMM-0.6 is designed for removal of contaminants, water and gases from insulating oils with viscosity below 70 mm / cm2 (cSt) at 50 °C. The plant is perfect for facilities engaged in installation, repair and operation of oil-filledRead More

Presentation of Equipment in Oman

Presentation of Equipment in Oman October 3, 2016: the city of Muscat in Oman hosted a seminar dedicated to the problems of oil, gas and electricity industries. The seminar was organized by RAY International Group and gathered around 50 participants from Oman, Norway and Germany. As part of the event, GlobeCore presented equipment for purification and regeneration of insulation oils,Read More

The oil border – transformer oil testing

The oil border – transformer oil testing Transformers are one of the main components of the complex equipment of many energy (power plants, substations, converter devices) or industrial enterprises. This equipment, depending on type and capabilities, can be operated in a wide range of conditions with varying load. Since transformers are an efficient energy transformation mechanism, it is important to maintain themRead More

Operation and maintenance of transformers

Operation and maintenance of transformers Operation of power transformers involves such processes as external inspection, measuring oil temperature and load, phasing, oil testing, corrective and preventive maintenance, overhauls etc. Inspection is performed once every six months. It includes checking the level of oil, checking for leaks and inspecting insulators. Each transformer should be equipped with a thermometer measuring the temperatureRead More

In Ecuador, the New CMM-12R Plant Started up Successfully

In Ecuador, the New CMM-12R Plant Started up Successfully August 25: representatives of GlobeCore arrived to Quito (Ecuador) to start the CMM-12R plant and train customer staff. Before a full start up, a test run of equipment was performed, which showed the following results of transformer oil regeneration: dielectric loss tangent: 0.7% at 90 ° C (initial value: 11%); breakdown voltage: 80 kV. NoteRead More

Preparation and Purification of Heating OilToday, heating oil is an easily available and a relatively cheap source of heat. Sometimes in books and articles on relevant topics one comes across the term “pyrolysis oil”, which is derived from the name of the process in which it is possible to obtain this heating fuel. Now heating oil has a tendency toRead More

Oil Pump Functions And ConfigurationOil pumps are used where it is necessary to keep constant circulation of oil: lubricating and pumping systems etc. Hence the purpose of these devices is circulation and pressure injection. Depending on the operating principle there are two types of oil pumps: gear and rotor. Gear pumps can have external gearing or internal gearing. TheRead More

Anti-Corrosion Tank ProtectionCorrosion is a negative process, which is basically a destruction of metal surfaces at the influence of environment. Ground-based metal tanks are subjected to atmospheric (external surfaces), air-vapor (roof inner surfaces and tank top rings) and soil (external surface of the tank bottom) corrosion. Atmospheric corrosion is a result of electrochemical processes. Thin film ofRead More

GlobeCore held a two-day training in cleaning diesel fuel in Germany

GlobeCore held a two-day training in cleaning diesel fuel in Germany June 30-July 1: GlobeCore conducted a practical training course in cleaning diesel for a US delegation. The event was held at the GlobeCore International Training Centre, located in Oldenburg (Germany). The interest of the American guests to GlobeCore equipment is not surprising. The company developed the CMM (UVR) plants , which clean and clarify differentRead More

Transformer Oil Processing PlantTransformer oil in most cases contains solid particles (metal oxides, cellulose fibers, etc.), water and dissolved gases. These impurities need to be removed. In practice special centrifuges with capacity of 10,000 L/h are used to remove emulsified moisture and bulk solids. The processed oil can be used for 35 kV voltage transformers. Vacuum degassing plantsRead More

Plant for Transformer Oil Regeneration is a New Life of TransformersThe problem of old equipment is constantly faced by the management of power plants. According to studies the number of power transformers, that were used for more than 25 years consists of 40%. Experts agree that most susceptible to damage are internal isolation of transformers and voltage regulators and bearings. Replacement of all old equipmentRead More

GlobeCore equipment commissioned at a new Al Kuwait transformer substation

GlobeCore equipment commissioned at a new Al Kuwait transformer substation On June 11-12, 2016 GlobeCore engineers have commissioned a CMM-4/7 degassing plant and BV-1000 vacuum unit at one of the new Kuwaiti transformer substations (Al Kuwait). The practice of commissioning modules consisting of several units is not so rare in electric power industry and is perfectly justified. In this case, it helps to resolve severalRead More

Drying and Cleaning of Transformer Oil

Drying and Cleaning of Transformer Oil Even the cleanest transformer oil coming from the manufacturer requires drying and degassing, as it is not possible to completely prevent the ingress of water and air. Also transformer oil can be contaminated with foreign particles during transportation. There are cases of incomplete removal of pieces of sorbents at the final stage of oil production.Read More

Fuller’s Earth (Fuller Earth): Features and Application

Fuller’s Earth (Fuller Earth): Features and Application Fuller’s earth is a natural material of grayish-white, brown, green, blue or olive color, consisting approximately 70% of silica. Its structure also includes: sapphire crystal, magnesium oxide, iron oxide and calcium oxide. Its present name Fuller’s earth received a few centuries ago, when masters of wool cleaning (“fullers”) began to use bleaching clay to removeRead More

Transformer Oil Treatment to Improve Reliability of Transformers

Transformer Oil Treatment to Improve Reliability of Transformers High cleanliness class of oil used in operation is a basic requirement for modern hydraulic and lubrication systems. Though manufacturers of oil-products do not always provide a proper level of cleanliness, forcing consumers to carry out additional treatment of oil before it can be used. In energy industry transformer oil is an important element. ItRead More

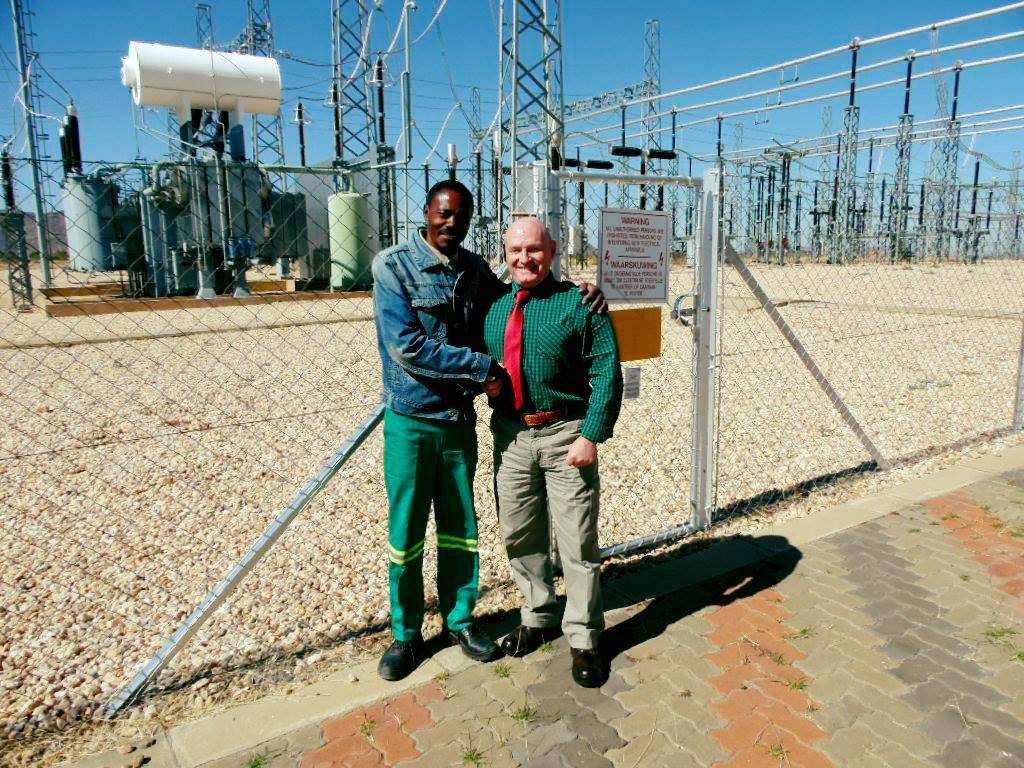

Working visit to Namibia

Working visit to Namibia June 1-2, this year, delegates from GlobeCore visited Windhoek (Namibia), and held several meetings with representatives of the Namibian electricity industry. During these meetings the GlobeCore delegates presented the company’s equipment for filtration, vacuum degassing and regeneration of mineral oil and equipment designed for atmospheric air drying and drying of solid insulation of transformers. MostRead More

Waste Oil Reclamation TechnologiesThe article analyses existing approaches to transformer oil reclamation. It considers acid and alkaline cleaning, vacuum distillation, rectification. It specifies the advantages and disadvantages of each method. In recent decades, mankind has been facing a threat of ecological catastrophe, This forces to revise procedures dealing with industrial waste, especially waste oil, an attitude of whichRead More

Fluids Filtration Systems in Mining Machines

Fluids Filtration Systems in Mining Machines Mining machinery is very expensive equipment. Its operation requires specific technical knowledge. Its effectiveness directly depends on maintenance, service and qualification of personnel. However the principal role is the quality of filtration of working fluid, which is subject to contamination due to intensive use. An appropriate level of purity of working fluid: increase service lifeRead More

Classification of Transformer Oil Purification FiltersAll the transformer oil filters can be divided into surface filters and depth filters. The structure of a surface filter includes a thin-layer filter membrane, where contaminants are retained on the surface of filter elements. This type of filters use a variety of fabrics, nets, paper, and materials capable of forming gaps. They retain impuritiesRead More

Turbine Oil Filtration

Turbine Oil Filtration The article considers types of turbine oil contaminants, as well as negative consequences to which they may lead. Application of GlobeCore oil filtration stations reduces costs of turbine oil operation, reduce oil consumption, increase its performance and avoid unscheduled stops of power plants. Prolonged operation of turbine oil leads to accumulation of various impurities inRead More

GlobeCore degassing units: the best solution for transformer oil processing

GlobeCore degassing units: the best solution for transformer oil processing Transformer oil contains up to 10% air (by volume) at atmospheric pressure. This significantly accelerates its oxidation and reduces dielectric strength. Therefore, the oil in large transformers must be degassed. Before putting the oil into the transformer, the residual gas content must be brought to less than 0.1% volume. The CMM-4/7 by GlobeCore is designedRead More

Waste Oil Purification TechnologiesThe problem of disposing of industrial waste is complex. Used mineral oil is formed as a result of operating of road transport as well as work of various industrial enterprises. Thus the problem of recycling of used mineral oils needs special attention. According to the existing regulation: engine, compressor, vacuum, industrial, gas turbine, instrument, transformerRead More

Waste Oil Recycling

Waste Oil Recycling Virtually any production is accompanied by large amounts of waste which can be reused after undergoing appropriate treatment. It is predicted that in the future, the new raw materials will be recycled from industrial waste. Used lubricant oil (ULO) is liquid waste product. ULO is any oil derived from crude oil or synthetic oil, contaminatedRead More

Waste Oil Collecting and Reclaiming

Waste Oil Collecting and Reclaiming Lubricating oil is practically always exposed to contamination during operation of machinery. Wear and tear are the first cause of contamination. Contaminated oil loses its resistance to oxidation, loses its lubricating properties and increases wear of the rubbing surfaces. Lubricating oil is constantly under the influence of high temperatures, atmospheric oxygen and deterioration products. TheRead More

Transformer oil restoration

Transformer oil restoration Transformer oil is used in power transformer an oil filled switches. This oil facilitate insulation of energized parts of the equipment, heat dissipation and arc extinguishing. The dangers of transformer oil contamination Electric power experts agree that the life time of a transformer lasts only as long as the life time of its insulation system.Read More

GlobeCore Holds a Seminar on Purification and Regeneration of Mineral Oil in Oldenburg

GlobeCore Holds a Seminar on Purification and Regeneration of Mineral Oil in Oldenburg April 21-22 this year, GlobeCore head office hosted guests from different countries. The office in Oldenburg was visited by specialists from the Czech Republic, Belgium and the UK to take part in a seminar on purification and regeneration of mineral oil. It should be noted that such events are organized by our company on aRead More

Silica Gel for Air Drying

Silica Gel for Air Drying Only porous materials, having a large specific surface, can be adsorbents. To dry air – silica is most commonly used. Silica gel is a result of dehydration of sodium silicate. The specific surface area of this adsorbent is 400-770 m2 / g and granule size – 0,2-7 mm. At the end of its effective operationRead More

Proper Maintenance of Transformer Oil

Proper Maintenance of Transformer Oil There are many factors influencing transformer oil. All of them need to be checked – to provide a good and reliable work of transformers. Contact with the atmosphere, high temperature and sunlight – are important factors that affect the quality of oil. And the higher the oxidation of transformer oil, the lower its dielectric strength.Read More

Regeneration of Waste Transformer Oil

Regeneration of Waste Transformer Oil During operation transformer oil is exposed to a variety of adverse factors: high temperatures, oxygen, moisture, sunlight, and others. Their overall impact leads to a significant deterioration of the insulating properties of transformer oil. It is moment when you need industrial purification systems. In order to preserve and extend service life of electrical equipment itRead More

GlobeCore opens a new service center in US

GlobeCore opens a new service center in US GlobeCore announced the opening of a new service centre in US. The address of the new location is 1750-H Dickinson Ave (FM 1266) Dickinson, TX, 77539. T: + 1-713-429-1616 and + 1-713-828-7877. Our other offices and service centers are available in the section “Contacts”.

GlobeCore Regeneration Technology Presented at Middle East Electricity 2016

GlobeCore Regeneration Technology Presented at Middle East Electricity 2016 1-4 March in Dubai the 41st annual Middle East Electricity 2016 exhibition was held. Over 1500 of international companies from 56 countries (total participant count was over 2000) gathered to present the newest development in electric power industry. The South African division of GlobeCore could not ignore such an event and participated with the demonstration ofRead More

A new waste sorbent reactivation unit developed

A new waste sorbent reactivation unit developed In the first quarter of 2016, GlobeCore completed the project of developing and manufacturing of the new CMM-4RP waste sorbent reactivation unit. This product us designed for restoration of waste bleaching earth sorbents, used industrially for purification of oils, heavy fuel, diesel and other petrochemical products. The waste sorbent is loaded into invertible columns ofRead More

Guests from Switzerland Visited GlobeCore German Office in Oldenburg

Guests from Switzerland Visited GlobeCore German Office in Oldenburg Guests from Switzerland visited GlobeCore German office in Oldenburg at the beginning of February Director and chief engineer of Swiss company wanted to learn about GlobeCore equipment for cleaning mineral oils and other petroleum products. Guests were shown UVP, CMM-R and CMM installations. For their better understanding of the principle of regeneration the samples ofRead More

Transformer Oil Bleaching

Transformer Oil Bleaching The exploitation of transformer oil leads to the loss of its original color. Oil discoloration is one of the indicators of profound physicochemical changes. There are various factors causing oil darkening, but they are mostly associated with its contamination by various impurities and oxidation products. Adsorption refining is the most effective technology in the performanceRead More

GlobeCore Starts Production of CMM-0.6 Oil Degassing Unit

GlobeCore Starts Production of CMM-0.6 Oil Degassing Unit At the beginning of December, 2015 GlobeCore successfully finished testing the new CMM-0.6 oil degassing unit. This CMM-0.6 unit has been designed and produced taking into account the demand for low cost, highly efficient units, intended for degassing dielectric transformer insulating oil. The CMM-0.6 unit can be used for pumping, heating, and degassing of dielectricRead More

Mojave Heat Hot Air Drying Unit Commissioned in Oman

Mojave Heat Hot Air Drying Unit Commissioned in Oman In mid-December 2015, employees of our Company successfully commissioned an automated Mojave Heat hot air drying unit in Oman. The Mojave Heat is used during installation and repair of power transformers for the purpose to ensure their integrity and airtightness. The Mojave Heat dries out the air to a temperature of up to +90ºC/194ºFRead More

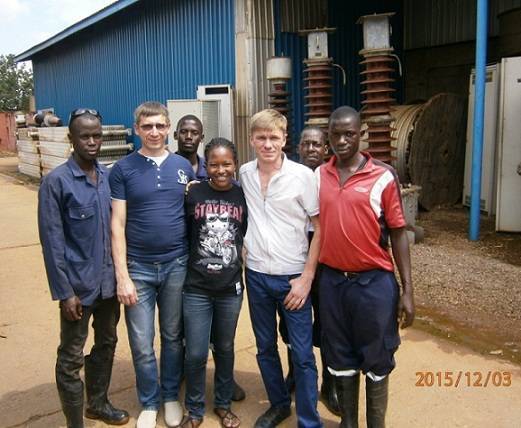

Another Successful GlobeCore Startup in Uganda

Another Successful GlobeCore Startup in Uganda On December 3, 2015, representatives of GlobeCore made a successful startup of a new CMM-4D oil processing unit in Uganda. The CMM-4D is based on the principle of thermal vacuum processing of dielectric insulating oil. In the vacuum column, the oil is being finely atomized, and special filters-activators provide for a larger area of itsRead More

GlobeCore Presents Its Equipment in Kyrgyzstan

GlobeCore Presents Its Equipment in Kyrgyzstan 7th to 11th December, 2015 GlobeCore representatives visited Kyrgyzstan (the cities of Bishkek and Osh). The main purpose of the visit – was presentation of equipment produced by the Company, as well as establishing new and strengthening existing business contacts. During the events representatives of the electric power industry of Kyrgyzstan had an opportunity toRead More

GlobeCore continues oil recycling equipment sales to Saudi Arabia

GlobeCore continues oil recycling equipment sales to Saudi Arabia A CMM-10 used oil degassing plant combined with the BV-200 vacuum unit have been in commissioning in Saudi Arabia from 14 to 17 December 2015. Various CMM units have already been commissioned in Saudi Arabia before. The demand on these units is due to their versatility: by purchasing just one unit, the client receives severalRead More

Commissioning of Regeneration Equipment in El Paso, Texas

Commissioning of Regeneration Equipment in El Paso, Texas In mid-November 2016, employees of our company commissioned the GlobeCore CMM-12R oil regeneration unit in the city of El Paso, Texas, USA. This equipment is designed for the complete regeneration of dielectric transformer insulating oil and can extend the service life of the power transformer up to 20 years or longer. The CMM-12R unit processesRead More

Vibration Control at GlobeCore

Vibration Control at GlobeCore GlobeCore is one of the leading manufacturers and suppliers of industrial equipment designed for use in the road building (road bitumen emulsion and modified bitumen production) and electricity industries (power transformer oil reclamation and oil purification). It is impossible to take the lead in any kind of activity without the full consideration of the needsRead More

Transformer Oil Processing Plants

Transformer Oil Processing Plants Oil derivatives account for a significant share of toxic waste produced by modern industrial facilities. These materials are a cause of water, soil and air pollution. Among the main producers of waste oil products are the electrical industry, chemical industry, metallurgical industry, and oil processing industry facilities. In the environment, these substances cannot be renderedRead More

Explosion Proof Oil Regeneration UnitUsed oil is a rather hazardous substance that cannot be biologically degraded under natural conditions. Most oil products will become a source of air, water and soil pollution if not disposed of properly. Just one liter of used oil can pollute more than a thousand liters of water. Waste oils, accumulated in the environment, disruptRead More

GlobeCore Equipment Presentations Held in Azerbaijan

GlobeCore Equipment Presentations Held in Azerbaijan A delegation of GlobeCore representatives visited Azerbaijan from the 12th through the 16th of October 2015. The GlobeCore representatives visited Baku and Gyandzha where they made four presentations and demonstrated the operation of the GlobeCore UVR-L laboratory unit. The various lines of GlobeCore oil processing and transformer service equipment were on display and demonstrations wereRead More