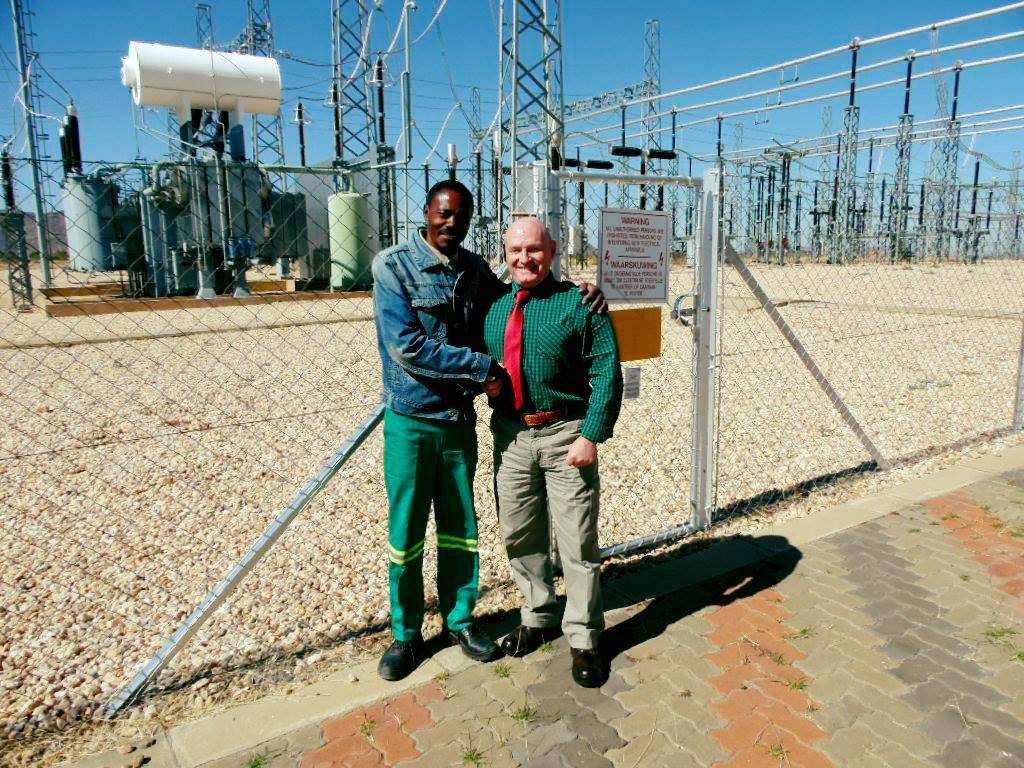

June 1-2, this year, delegates from GlobeCore visited Windhoek (Namibia), and held several meetings with representatives of the Namibian electricity industry.

During these meetings the GlobeCore delegates presented the company’s equipment for filtration, vacuum degassing and regeneration of mineral oil and equipment designed for atmospheric air drying and drying of solid insulation of transformers.

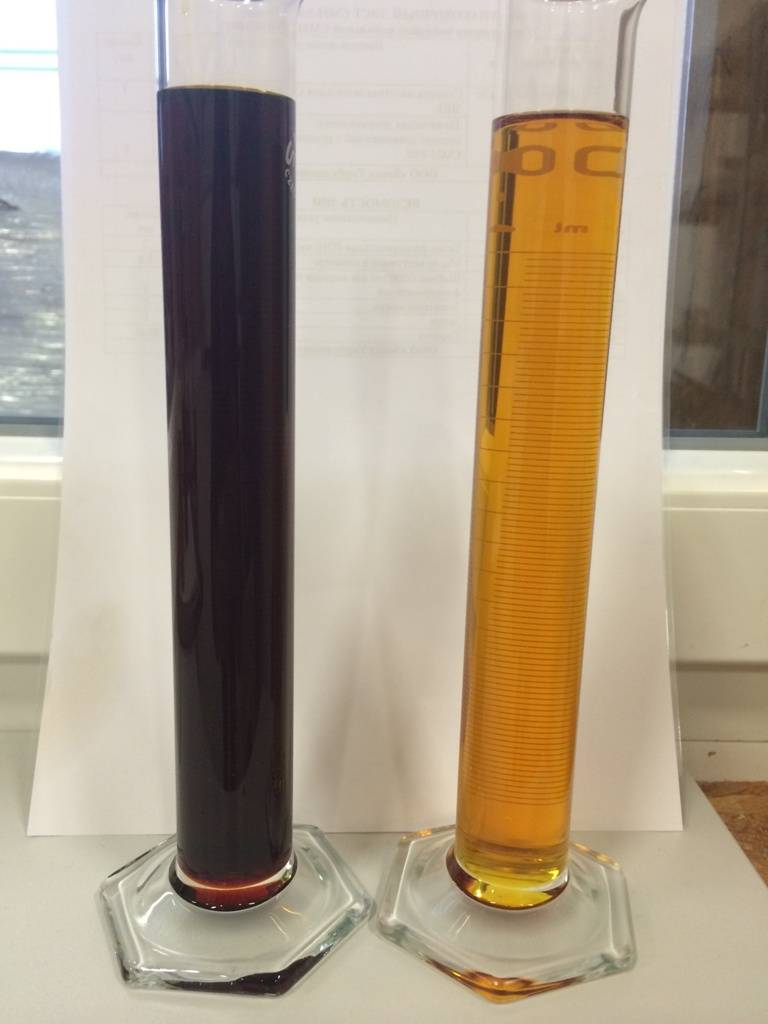

Most attention was drawn to the UVR regeneration unit. This equipment uses a unique technology of processing mineral oil with a special sorbent, which cleans and restores transformer, turbine and industrial oils, as well as diesel fuel, gasoline, kerosene, heating oils etc.

In the course of the presentation there was a practical demonstration of the UVR laboratory unit, purifying contaminated samples of hydraulic fluid. The contaminated fluids were kindly provided by the representatives of Botswana, who were also present at the event. After processing, the oil recovered its original color and restored its performance characteristics.

On the whole, the trip to Namibia can be regarded as successful. GlobeCore once again had a fruitful dialog with the representatives of the electricity industry. New agreements were reached for the production and supply of oil equipment to South Africa.