International market of turbine oil purification technologies

International market of turbine oil purification technologies

GlobeCore is one of the world leaders in production of industrial equipment for blending, purification and regeneration of liquids and fuels.

Due to the continuing growth of the industry worldwide, the issue of mineral resource depletion becomes increasingly important. The decrease of the world’s deposits of mineral resources, difficulty in mining and drilling in the remote areas of the planet or unstable political situations increase the cost of the resources and monopolization of the supply.

Therefore, GlobeCore’s reclamation products are in special demand.

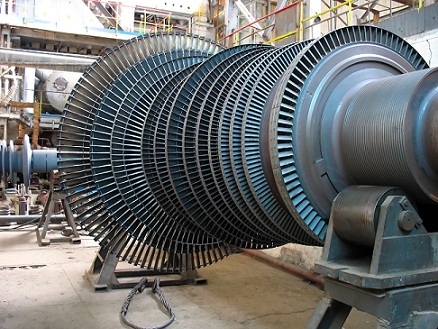

Turbine oil, as one of the sub-types of industrial oil is used in various turbine machines. It is an indispensible part of equipment, being a coolant and a lubricant for bearings and friction parts.

Due to the fact that turbine oil is used in difficult conditions, the oil is subject to accelerated aging.

The most important factor of turbine oil oxidation is the constant influence of high temperatures in turbines. Heat results from friction of bearings in oil film (especially support bearings, which may carry varying loads in different parts) or due to energy transferred from hot parts to the shaft. Since the oil’s oxidation greatly increases past 80oC, overheating conditions in the cooling and regulation systems must be carefully avoided in proximity to the turbine’s hot surfaces and steam lines. Overheating greatly degrades the oil’s parameters.

Air, which is present in the oil or enters from the outside during operation of equipment, in combination with other factors, promotes oxidation of oil. Bubbles of free air compress after passing through the main oil pump. The compressed bubbles then solve in the oil and saturate it with such contaminants as dust, ash, steam etc. This is especially true for turbines where oil pressure after the main pump is quite high. This leads to rapid heating of air in the bubbles and oxidation.

Moisture in the oil is one of the worst results of contact of oil with hot steamThis also accelerates oil aging. The low molecular acids dissolve in water and corrode metal surfaces of the turbines. Presence of water in the oil facilitates formation of sludge, which settles on the surfaces of the oil tanks and oil supply lines. It also enters bearings and may clog the openings of portioning washers, or cause overheating of a bearing. In several cases, the friction parts were so hot that they some melting occurred.

Contact with various metals is also a factor in oil oxidation. Oxidized oil corrodes metal surfaces. Another danger is the rotating parts of the turbine: couplings, gears, shafts etc, which cause oil spraying, which comes into contact with air and oxidizes further.

Aging of oil degrades its properties and limits its benefits. The rate of oxidation depends on the manner in which the oil is used and the individual characteristics of the turbine and its oil system.

The main condition of quality oil operation is systematic quality control. Deviations from normal parameters may lead to unforeseen malfunctions. If the turbine oil deteriorates faster than normal, its service life should be limited.

To avoid the costs of disposal of used liquids, which cannot be used anymore due to hazard to the turbine equipment, the oil is purified and regeneration by special plants.

CMM type mobile plants are designed for restoration of oil: removal of degradation products and acids, lightening of oil, improvement of oil stability and reduction of gas solubility. Regeneration of turbine oil is performed on site and helps to remove sludge by using a reactivable sorbent.

This technology is highly efficient, while the tests show the outstanding results of turbine oil regeneration, restoring the oil’s original specifications.