High vacuum transformer oil degassing plant CMM-4/7D (capacity 4000 LPH)

High vacuum transformer oil degassing plant CMM-4/7D (capacity 4000 LPH)

GENERAL INFORMATION

| The unit may be used for heating of oil-filled electrical equipment by hot transformer oil, vacuum transformer drainage and transformer dry-out. Unit is used for installation, repair and maintenance companies which are dealing with transformer oil treatment. The unit is not fit for operation in explosive or toxic environment, as well as environment reactive to lubrication materials. When operating the unit indoors, install gas exhaust line to evacuate gases into the atmosphere. |

|

| Performance in a single pass through the purifier at a full flow rate shall be as follows: Water Removal: From 100 ppm down to less than 10 ppm as measured by ASTM method D-1533. Gas Removal:From fully saturated with air (10 to 12% by volume) down to less than 0.25% by volume as measured by the ASTM Method D-2945 Particulate Matter Removal: 98% of particles over 2 μm Dielectric Strength: Improvement in dielectric strength up to 70 kV. |

TECHNICAL DATA

|

Parameter |

Value |

|

| 1. Capacity, m3/h, | ||

| – in degassing, dehydration and filtration mode |

0 – 4.0 |

|

| – in heating and filtration mode |

up to 7.0 |

|

| 2. Capacity adjustment range, m3/h |

0-4.0 |

|

| 3.PedroGil RVB 20.20 Roots vacuum pump capacity, m3/h |

280 |

|

| 4.* Processed oil parameters : | ||

| – maximum gas content, %, max. |

0.1 |

|

| – maximum moisture content, ppm, |

5 |

|

| – ISO 4406 industrial purity class |

9 |

|

| – mechanical impurities content, ppm, max | 8 | |

| – filtration rating, micron | 2…25 | |

| -breakdown voltage, kV, minimum | 70 | |

| 5. Maximum oil outlet temperature in heating mode , ºС |

85 |

|

| 6. Filtration coefficient |

>50 |

|

| 7. Outlet pressure, MPa |

0.35 |

|

| 8. Delivery head, m |

35 |

|

| 9. Oil heater power, kW |

50 |

|

| 10. Oil heater mean power, W/cm2, max |

1.1 |

|

| 11. Maximum power consumption, kW, max. |

63 |

|

| 12. Power supply parameters, 3 Phases + Neutral grounded |

|

|

| – voltage, V |

as required |

|

| – AC frequency, Hz |

50/60 |

|

| 3. Dimensions w/o trailer, max., mm |

|

|

| – length |

1625 | |

| – width |

1250 |

|

| – height |

1590 |

|

| 14. Weight, kg, max. |

920 |

|

Note – * For inlet oil parameters as follows:

– gas content by volume less than 10,5%

– moisture content by weight less than 0,01% (100 ppm)

– temperature above 5 ºС.

TECHNICAL DESCRIPTION OF EQUIPMENT.

Configuration

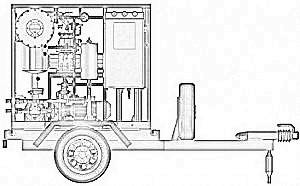

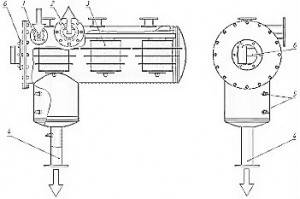

The Unit (figure1.1) is an assembled container keeping all the

junctions, components and aggregates. Container is the one- or biaxial trailer

mounted. Front as well as back wall is lockable doors mounted for unobstructed

access and fanning. Unit is supplied mounted on two-axial trailer equipped by

torsional suspension axles, pneumatic wheels, coupling loop, support jacks,

pneumohydraulic braking system, parking brake hand lever and electrical

equipment.

|

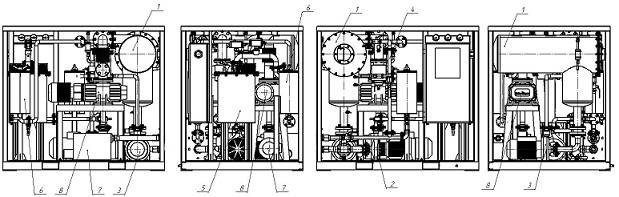

There are the following components inside the frame: vacuum column 1, inlet oil pump 2, outlet oil pump 3, oil heater 5, fine filters 6, control panel (complete control unit CCU), vacuum pumps cluster, pipeline system with shut-off and control valves 4. To adjust parameters, Unit employs temperature controllers 2ТRМ «Оven» (equipped with ТСМ sensors), vacuum controllers RVE-4,1 (equipped with PМТ-6 lamps), both pressure and vacuum gauges(М1-М3). Figure 1.1. General view |

|

Figure 1.2. Unit general view

1 – vacuum column, 2 – input pump, 3 – output pump, 4 – pipeline system, 5 – oil heater, 6 – coarse (25 micron) and fine (2 micron) filters, 7 – vacuum backing pump СР 40-620, 8 – booster (Roots) pump RVB-20.20.;

|

|

Pumps 2 and 3 supply transformer oil into the Unit and suck it out respectively. The pumps are controlled from the control panel.

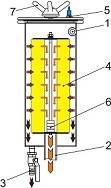

Coarse and fine filters 6 purify the oil being processed. Filtration fineness is 25 and 2 micron. For filter general view see figure 2.

|

Figure 2. Cartridge filter

1 – inlet oil pipe branch; |

The filtering elements (cartridges) are easy to replace and cleanable.

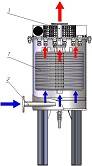

Oil heater 5 (figure 1.2) is a chamber keeping 2-sections heating cluster, inlet and outlet pipelines, as well as drainage valve. For oil heater overview watch figure 3.

| Figure 3. Oil heater1 – oil heating block; 2 – cold inlet oil pipe branch; 3 – heated outlet oil pipe branch |

|

Use separate control switch buttons for each of two heating stages to manage overall cluster. Operate either each separate or all heating sections simultaneously (mode capacity results in operating section; thus, one stage is sufficient for degassing mode as long as heating and filtering mode supposes two-stage operating).

Employ temperature control sensor Th1 (Figure 6) to control oil temperature when heated.

Flow relay PП indicates operational fluid flow to prevent heating section failure and oil overheating. Heater is interlocked by a flow switch and is being energized only when oil is flowing through it. Heater is equipped with separate thermostat TS for extra-control and protection against overheating interlocked with heating elements.

Vacuum column 1 is designed for degassing of transformer oil. For column overview watch figure 4.

|

Figure 4. Vacuum column1 – inlet pipe branch; 2 – vacuum system connecting pipe branch; 3 – activating filter (sprayer); 4 – treated oil outlet pipe branch; 5 – level indicator; 6 – sight glass with illumination |

Residual pressure of no more than 267 Pa is maintained in the column in the process of oil degassing. Oil is transported to the column by inlet pipe and through the collector to the activating filters (sprayers).

Sprayer design allows for oil intensively exhaling gases and moisture.

| Control cabinet is designed for placement of electrical components to facilitate Unit operation. It is a metal cabinet with lockable door. Electrical control and commutation circuits are panel located inside. Control buttons and light signalling devices are installed on the cabinet. For control cabinet general view watch figure 5.

Figure 5. General view of control cabinet panel

|

|

Column’s residual pressure is controlled by electronic vacuum controller RVE-4.1. Limit of effective measuring range is 0,133÷105 Pa.

When operated oil heater is controlled by following measuring gauges:

– thermostat – for oil heater switch off if oil temperature is above 90º C set;

– flow relay – for oil heater switch off if no oil flow is supplied through oil heater;

– thermistor – for oil temperature measuring on heater outlet;

– manometers – to indicate contamination level of filter elements with regard to inlet and outlet pressure in fine filters;

– level indicators – to control oil level in vacuum column.The unit can be operated in the following modes:

– oil pumping;

– oil heating and filtration;

– oil dehydration and degassing;

– vacuumizing of external equipment.