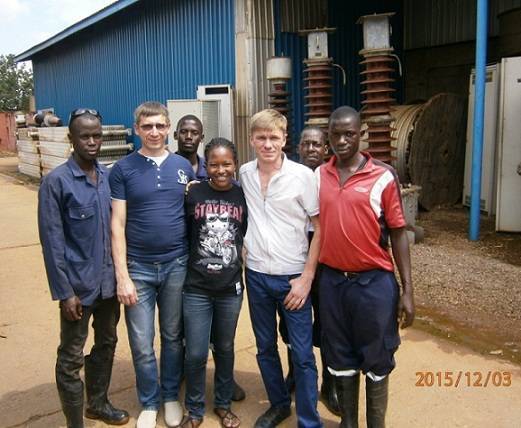

On December 3, 2015, representatives of GlobeCore made a successful startup of a new CMM-4D oil processing unit in Uganda.

The CMM-4D is based on the principle of thermal vacuum processing of dielectric insulating oil. In the vacuum column, the oil is being finely atomized, and special filters-activators provide for a larger area of its processing.

The CMM-4D unit can be utilized for:

- cleaning of transformer oil by removing mechanical impurities, water, and gases;

- heating of electrical apparatuses with transformer oil in electric substation;

- vacuum drying of transformers; and

- vacuumizing of equipment.

The equipment is easy to operate and maintain, and it provides consistent processing parameters of insulating oil (filtration fineness is 5 microns and the purification degree is up to the 9th class of purity).

The GlobeCore CMM-4D unit can be operated in the following modes:

- oil transfer;

- warm-up of transformer;

- heated filtration and thermal vacuum purification of the oil; and

- vacuumizing of equipment.

The unit is equipped with the necessary means of protection and automation that enhance the reliability of its performance. In particular it can:

- control the oil heating temperature;

- protect the unit heater from overheating;

- monitor the presence of oil flow through the heater; and

- adjust the oil heating temperature in accordance with the pre-set mode.

If you need an efficient and reliable unit for the purification and degassing of transformer oil that can also perform a number of additional useful functions, then the CMM-4D transformer degassing unit is a perfect choice! You can make a purchase order by contacting us through one of the given contacts.