Energy industry: what can influence turbine oil?

Industrial oils, a term which usually implies products of oil refining used in various industries, can be roughly divided into several types.

Some mineral and synthetic oils are made for lubrication, cooling and stabilizing the internals of turbines, pumps, turbo compressors etc. One of the most important oil parameters is viscosity. The lower the viscosity, the better the oil’s heat conductivity is. If the viscosity of the oil in a transformer is too high, the transformer will not be cooled efficiently. Overheating becomes an unpleasant possibility. Turbine oil viscosity usually varies in the range from 10 to 60 mm2/second.

Just as any other oil, turbine oil can age. Oxidation is promoted by several factors. One of such factors is elevated temperatures, which is inevitable for turbine oils. Therefore, maintaining physical stability of oil in the process of operation for as long as possible is especially important for this type of oils.

Control of turbine oil condition is one of the most important things in using the oil. Sediment on friction parts, formation of various liquid compounds and contamination by metal chips from the turbine all lead to grave consequences.

Research into industrial liquid control and service, additional purification measures for removal of air, water and other contaminants is especially important for turbine oil. Even though oil producer may guarantee high quality and purity of the oil, the oil may still become contaminated during transportation and storage.

In this case, when the buyer is also partly responsible for the purity of the products, it is in the buyer’s best interest to procure equipment which can quickly and efficiently bring the oil back to the required specifications.

As mentioned above, turbine oil aging is accelerated by water, air and contaminants. The result is oxidation of oil, hydrolysis, deterioration of oil properties, degradation of the lubricating film protecting the internals of the machinery, which all lead to corrosion and possible damage to equipment.

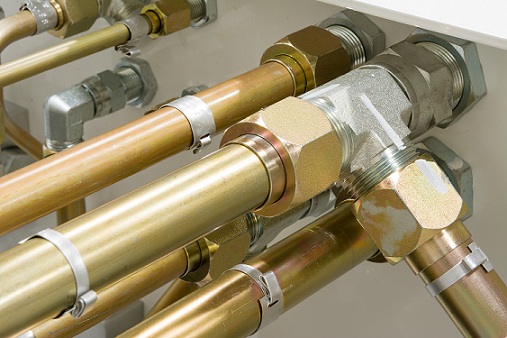

There is a wide range of turbine oil purification plants in the market: from simple portable units to comprehensive purifiers of turbine oil designed for removal of solid particles, water and gas.

The CFU plants are a simple example of turbine oil purifiers. These systems remove ash, free and some dissolved water, water soluble acids and alkali.

Oil is purified by heating, vacuum and passing through coarse and fine filters.

Simple mobile plants are often designed for a certain type of oil with specific parameters.

CMM type plants are equipped with more power pumps and better filters. These units feature several modes of operation selectable from the control panel:

-

Oil heating and filtration;

-

Oil drying, filtration and degassing;

-

Vacuum evacuation of external equipment.

The customer’s selection is limited only by financial considerations. There is no need to wait. All equipment necessary to save on failure repairs and downtime are readily available from the industrial manufacturers.