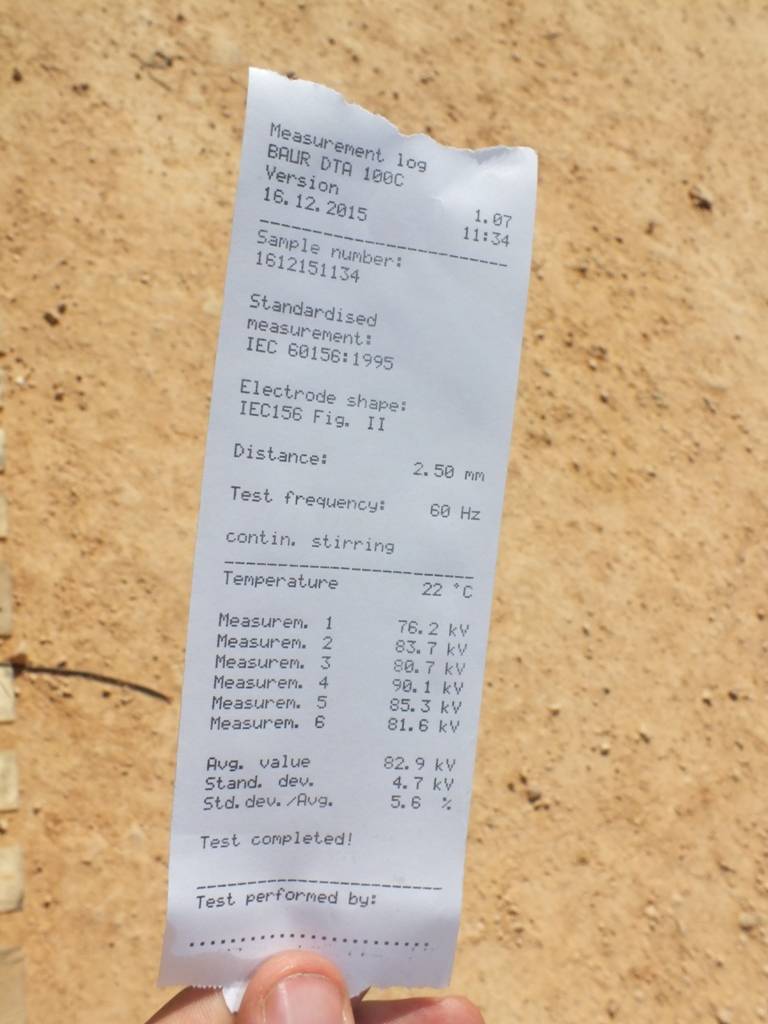

At the beginning of December, 2015 GlobeCore successfully finished testing the new CMM-0.6 oil degassing unit.

This CMM-0.6 unit has been designed and produced taking into account the demand for low cost, highly efficient units, intended for degassing dielectric transformer insulating oil.

The CMM-0.6 unit can be used for pumping, heating, and degassing of dielectric insulating oil, as well as removing mechanical impurities and moisture. The processing capacity of the unit is 0.6 m3/hour.

The unit has a relatively simple design and consists of the vacuum column, ceramic heater, fluid pump, vacuum pump, and filtering system with replaceable cartridges.

Sensors have been installed in the unit so that the operator can control the pressure drop at the filters and control the amount of working vacuum. The heating temperature can also be controlled through the use of a special regulator.

When processing/treating a transformer with high moisture content in the oil, there is always a possibility of foam formation, therefore, in order to avoid this problem a special type of protection is provided for in the unit. If, for some reason, oil begins to leak or spill from the unit, the oil spill will be immediately detected by the “Oil Spill Sensor” and the unit will be shut down at the same alerting the operator with an alarm.

Technical Specifications of CMM-0.6 Oil Degassing Unit

| No. |

Parameter Description

|

Value

|

| 1 |

Efficiency, m3/hour |

0.6

|

| 2 |

Power supply (AC 50Hz, V) |

380*

|

| 3 |

Rated input power, kW |

14

|

| 4 |

Pre-filter, micron |

200

|

| 5 |

Degree of filtration, microns |

5

|

| 6 |

Cleanliness level after processing (as per ISO 4406) |

-/14/12

|

| 7 |

Oil breakdown voltage after one cycle of processing not less, kV |

60**

|

| 8 |

Outside dimensions (excl.hoses) not more, mm |

|

|

— length |

750

|

|

— width |

520

|

|

— height |

1350

|

| 9 |

Weight (without oil) not more, kg |

250

|

* – any voltage available at customer’s request;

** – provided that the processed oil has not been in use.

The GlobeCore CMM-0.6 unit has the following advantages:

- compact size;

- ease of maintenance and operation;

- silent operation; and

- the ability to be powered through a conventional 220 electrical outlet.

You can purchase the CMM-0.6 degassing unit right now by contacting one of our managers on the contact list.

In order to change the default parameters to your specific needs, the Customer must fill out a questionnaire, wherein you should include the necessary technical requirements.